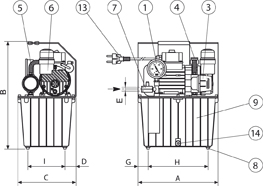

Portable Vacuum System (CPV 4/8) This unit is intended for applications in the construction industry and where a practical and easily portable buffer is needed, eg. using suction cups or lifting equipment.

The unit consists of a container of anodized aluminum with galvanized top and a 4 m3/h oil-lubricated vacuum pump. The vacuum system is connected with a ball valve which is also connected to a vacuum gauge which constantly shows the degree of pressurization in the container.

Standard equipment includes start/stop button, power cable and the possibility of emptying the tank. In addition, it can be purchased with a switch that automatically stops the vacuum pump if the tank becomes full with liquid.

Vacuum system with liquid separator.

These vacuum systems are designed and built for use on glass and marble machines and on machines where it is possible to consume non-aggressive liquids (normally coolants).

These are complete and compact vacuum systems and are usually connected to the application of a flexible hose. A ball valve at the tank inlet makes it possible to cut off the maintenance application. Air and liquid are first separated in the tank by means of an internal “cyclone” device.

The air in the tank, without droplets but still moist, passes through a condensation separator filter on which a vacuum gauge is mounted to control the operation of the vacuum system and a ball valve for the return air (this is necessary to empty the collected water in the tank).

The filter is connected to the pump through a pipe with a built-in extra valve.

The pumps used in these vacuum systems belong to the WR series, which has a built-in high-efficiency “gas ballast” unit that allows residual condensation to separate the oil and separate the condensate with the vacuum pump stopped.

The pumps are also used to drive centrifugal pumps with centrifugal pumps, and with great success. Especially tool companies around Denmark have chosen to buy this pump unit, after we have implemented a protective device that automatically switches off the pump when the centrifugal pumps are diluted.